This time I did a freezer paper stencil with gold metallic paint to make the road stripes. It saved me a lot of time and I really like the look.

I made the pj’s that my son is modeling a while ago. They were one of the first projects that Haley and I worked on together. The top is one of Dana’s 90-min shirts (We were able to fiddle with the directions and get it down to 55 min but only if the kids weren’t bugging us.) As you can see they have gotten a little snug so for day five of the Kid’s Clothing week challenge I made a new set of bottoms and a matching ringer shirt for the top. I’m thinking about adding a stencil to the top but I also like that right now he could wear it as a normal shirt too.

I also made this pair of flannel pants using a store bought pattern. I really don’t like the fit of them, I think they were made for a non- diapered butt. On top of the poor fit, the elastic casing fell apart in the wash so I’m counting this as a fail.

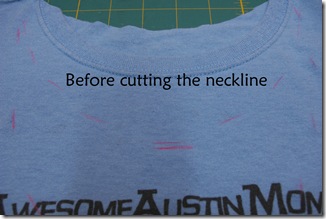

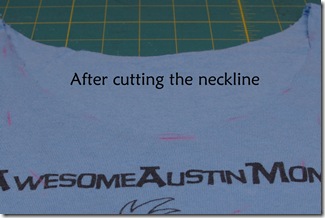

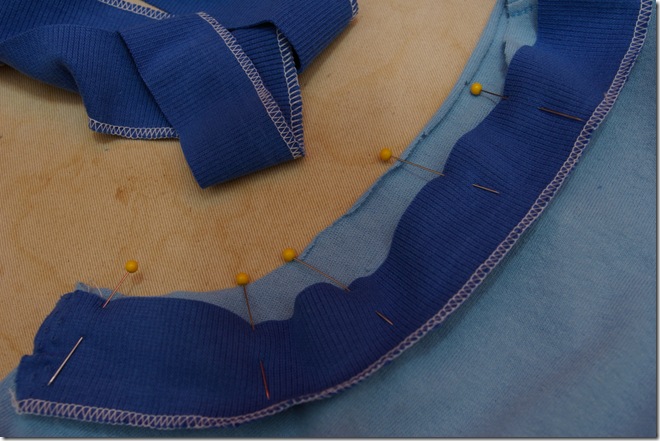

Day Three was a major fail for me. I used a tutorial from crafterhours to make a ringer shirt. The tutorial is great, this pattern failed because of my inexperience in pattern making. I made a pattern on a t-shirt I already owned and then cut it out one of my husband’s old shirts. It wasn’t until after I finished the shirt that I was able to see my giant mistake. The size of the neck hole could fit around my waist. When I tried it on Ash I laughed as he looked like an eighties dancer with this shirt hanging off his shoulders

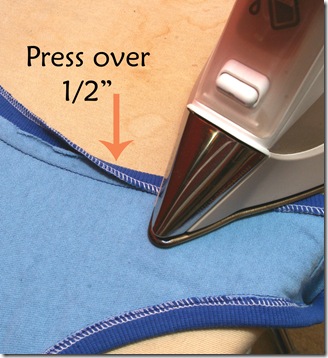

Lucky for me my partner in crime has substantially more experience than me and was able to show me exactly how to adjust the pattern to take in the neck. I thought I should lengthen the shoulder seam to decrease the neck line but Haley showed me how a simple pinch at the neckline can decrease the size of the hole with out changing any other dimension.

So on day four I tried another ringer shirt and it came out so awesome and fast that I made a second one immediately after.

I had no idea there was a second star shirt but when I dressed one of my men the other decided to match

It was a successful two days for yours truly. Four upcycled shirts complete! Cam’s daddy was nice enough to sacrifice some shirts for a good cause.

Tomorrow…Cam gets pants.

I decided to try and make a tag for today's Kid’s Clothing Week Challenge Item. I made this with some scrap fabric and a fabric marker. We’ll see if it holds up in the wash.

Maybe I’ll get some professionally printed. Any recommendations on where to get some made? I’m on a tight budget these days so I can’t spend too much.

hard could it be to make a quick little baby diaper?

hard could it be to make a quick little baby diaper?

Did you know there is a national holiday for Play Doh? September 16th. Seems like a great excuse to make a giant batch and invite some friends over. Luckily, my friend Julie gave me her recipe just the other day. I love the texture. All the homemade Play Doh I’ve used in the past has been really grainy but this recipe gave super soft dough without the Play Doh scent. I also have a 12 pack of Wilton food coloring so I kept making it until I ran out of colors.

Did you know there is a national holiday for Play Doh? September 16th. Seems like a great excuse to make a giant batch and invite some friends over. Luckily, my friend Julie gave me her recipe just the other day. I love the texture. All the homemade Play Doh I’ve used in the past has been really grainy but this recipe gave super soft dough without the Play Doh scent. I also have a 12 pack of Wilton food coloring so I kept making it until I ran out of colors.